Hello Building-Integrated Agriculture Enthusiasts! It has been one year since the launch of this blog and we are happy to report that dense urban agriculture has truly been experiencing a boom over the past year. We have reported on a lot of companies and projects that were only ideas that are now being built and implemented throughout the world. We will say it again: we are on the verge of a sustainable urban agriculture revolution. To celebrate, we recommend that you read this WSJ article on the phenomenon of building-integrated agriculture and some of the projects that have come to life over the past year.

Future of Agriculture May Be Up

The seeds of an agricultural revolution are taking root in cities around the world—a movement that boosters say will change the way that urbanites get their produce and solve some of the world’s biggest environmental problems along the way.

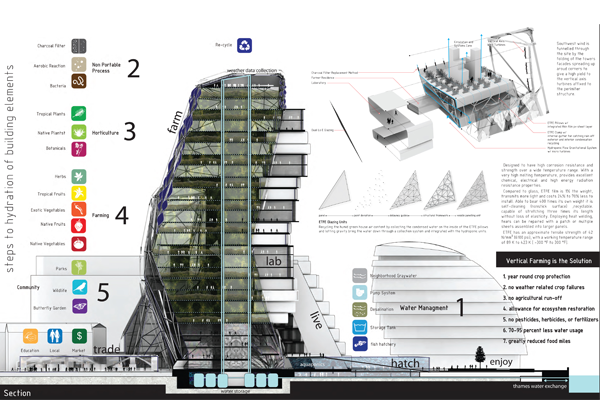

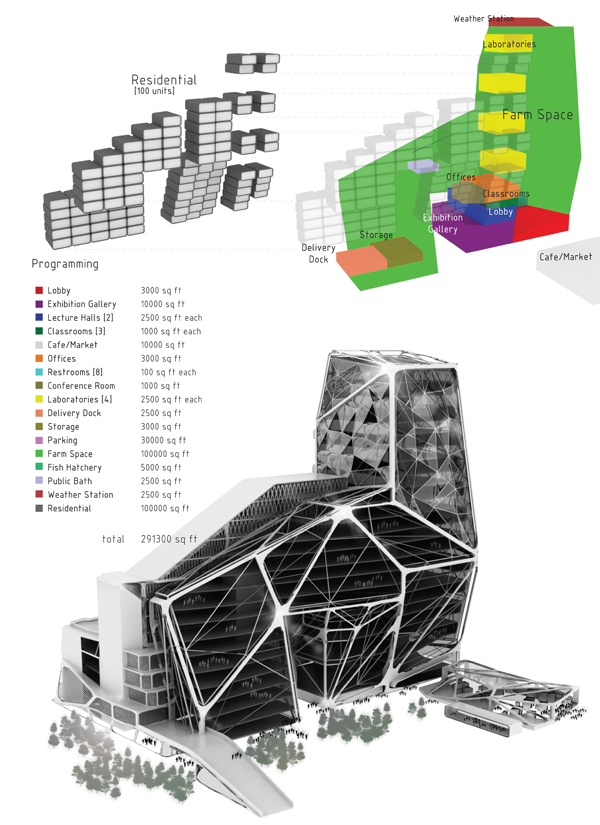

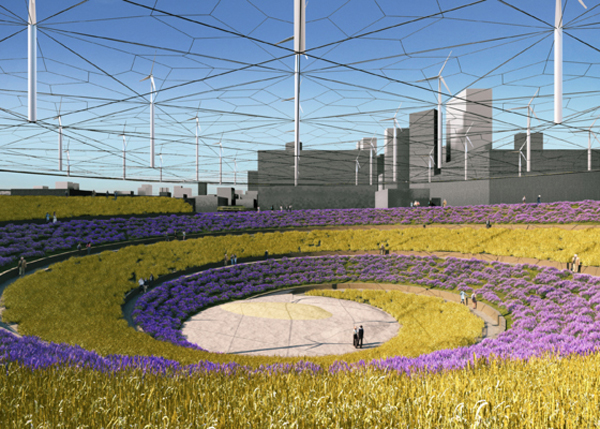

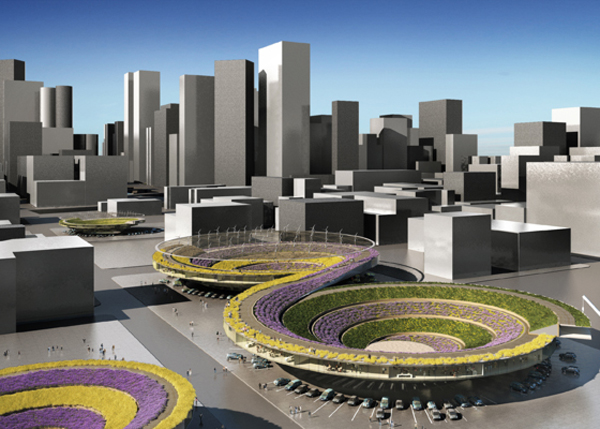

It’s called vertical farming, and it’s based on one simple principle: Instead of trucking food from farms into cities, grow it as close to home as possible—in urban greenhouses that stretch upward instead of sprawling outward.

The idea is flowering in many forms. There’s the 12-story triangular building going up in Sweden, where plants will travel on tracks from the top floor to the bottom to take advantage of sunlight and make harvesting easier. Then there’s the onetime meatpacking plant in Chicago where vegetables are grown on floating rafts, nourished by waste from nearby fish tanks. And the farms dotted across the U.S. that hang their crops in the air, spraying the roots with nutrients, so they don’t have to bring in soil or water tanks for the plants.

However vertical farming is implemented, advocates say the immediate benefits will be easy to see. There won’t be as many delivery trucks guzzling fuel and belching out exhaust, and city dwellers will get easier access to fresh, healthy food.

Looking further, proponents say vertical farming could bring even bigger and more sweeping changes. Farming indoors could reduce the use of pesticides and herbicides, which pollute the environment in agricultural runoff. Preserving or reclaiming more natural ecosystems like forests could help slow climate change. And the more food we produce indoors, the less susceptible we are to environmental crises that disrupt crops and send prices skyrocketing, like the drought that devastated this year’s U.S. corn crop.

Dickson Despommier, a microbiology professor at Columbia University who developed the idea of vertical farming with students in 1999, thinks vertical farming will become more and more attractive as climate change drives up the cost of conventional farming and technological advances make greenhouse farming cheaper. In fact, he hopes the world will be able to produce half of its food in vertical farms in 50 years.

Then “a significant portion of farmland could be abandoned,” he says. “Ecosystem functions would rapidly improve, and the rate of global warming would slow down.”

A host of vertical farms are up and running in the U.S. and overseas, and others are under construction. Some are backed by nonprofits aiming to promote environmental causes or local job creation. Others will be for-profit ventures meant to meet demand for local produce. And some, like one in South Korea, are being funded by governments looking for ways to boost domestic food security.

So far, vertical farms are producing only a small amount of food. Advocates are still developing different building designs and growing techniques to boost the efficiency of cultivating food indoors. And a proven business model based on the concept has yet to emerge.

One ambitious project under construction is trying to address all of those challenges at once. At 12 stories, the triangular farm in Linköping, Sweden, will be one of the tallest vertical farms in the world—most max out at several stories—and will use innovative ways to generate revenue. Not only will the company behind the farm, Sweden’s Plantagon, sell its produce at a local farmer’s market, but it also will lease out office space on most floors.

Another unique feature: Outside the office windows, on the building’s southern face, a mechanical track enclosed in its own layer of glass will carry growing plants from the top of the building to the bottom floor. The arrangement is meant to give the plants even exposure to sunlight and allow Plantagon to perform all of its planting and harvesting in one place—on the ground floor. (After planting, a normal vertical elevator takes the boxed plants to the top floor to start their voyage down.) The company plans to produce 300 to 500 metric tons of leafy greens like bok choy a year.

As for the price tag, “it’s much more expensive, of course, to build a greenhouse vertical than to build a normal greenhouse,” says Hans Hassle, Plantagon’s chief executive. But the planned revenue streams will help make up for that, and energy costs will be lower because the setup will use waste from various sources—such as heat from a nearby power plant and biogas produced through conversion of the building’s own organic garbage. All told, the planned energy-saving measures will reduce the building’s energy use by at least 30% to 50%, Mr. Hassle says.

Mr. Hassle says the company’s next greenhouse will be either a demonstration model in Shanghai or a research facility in Singapore. These are good venues for the idea, he says, because they’re highly dense and urbanized societies that already need to produce more food locally.

In the U.S., vertical farms are sprouting in urban areas across the country, some in old buildings that have been re-purposed for agriculture. One operation called the Plant is producing vegetables in a three-story former meatpacking facility on Chicago’s South Side.

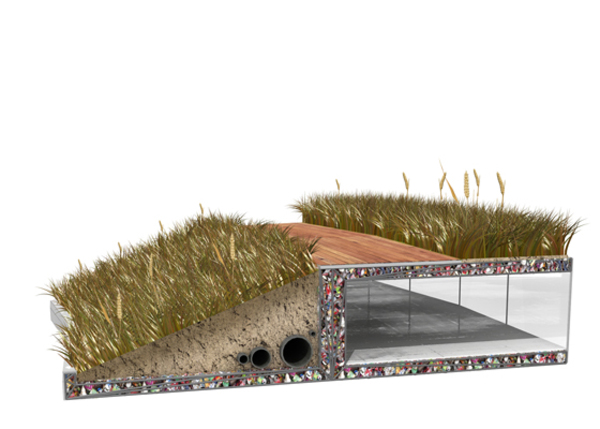

The farm grows vegetables on small rafts floating on water, which is filled with nutrients from waste produced by fish in a separate tank—a setup called aquaponics. Light comes from lamps designed to emit the proper wavelengths for plant growth. The Plant is also designing a growing system in which crops could grow sticking out at an upward angle from vertical boards, with nutrients provided to the plant roots by water dripping down a film from pipes near the ceiling.

The Plant was founded by John Edel, a 43-year-old Chicago native who has led other projects to renovate and reuse urban buildings. The facility currently rents out parts of its space to tenants including three farmers and two bakeries and plans to find more; it also intends to open a shared retail area where the tenants can sell their goods.

Other farms around the country use different techniques designed to save space, reduce water consumption and even avoid the need for soil. Farms in warehouses and other buildings in Seattle, Chicago, upstate New York and New Jersey, among other places, use an aeroponics system from AeroFarms of Ithaca, N.Y. The method involves growing plants with their roots hanging in the air, where they can be sprayed with water and nutrients.

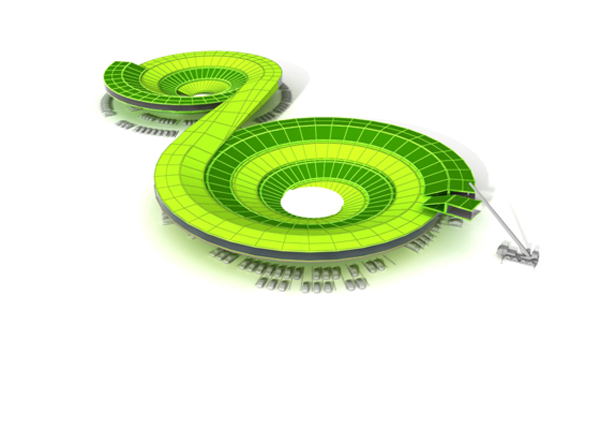

Omega Garden Inc., of Qualicum Beach, British Columbia, sells a planting device called Volksgarden, a rotating cylinder four feet in diameter and two feet long. Plants grow in a circle around the inside of the cylinder. As the device rotates, their roots dip into a tray holding a liquid solution that provides water and nutrients. A light runs horizontally through the cylinder to nourish the crops.

Green Spirit Farms LLC is using the system in New Buffalo, Mich., in a former plastics-injection facility. The farm plans to fill the space with Volksgarden units stacked three levels high, says Green Spirit site manager Ben Wiggins.

Still, many agricultural experts aren’t sold on the idea of vertical farming. The core argument against it: Conventional farms are the simplest and most efficient places to produce food. Growing food indoors, using artificial lights and other special equipment, means more effort and expense—and cancels out any benefits of being close to customers, critics say.

That’s why George Monbiot, a writer and environmental activist based in Oxford, England, says there’s “no prospect” that more complicated vertical-farming techniques could contribute substantially to world food production. As for those vertical farming systems that will consume extra energy to power equipment like artificial lights, he says, “Even if you are taking the energy from renewable sources, there are better ways of using that renewable energy.”

Likewise, R. Ford Denison, an adjunct professor of agricultural ecology at the University of Minnesota, thinks the energy use from vertical farms would cancel out any fuel savings from transportation. “Food transport from farm to store is a tiny fraction of total agricultural energy use,” he says. So if vertical farms use even small amounts of energy to run their systems, or if consumers have to use extra fuel traveling to urban farmers’ markets, it “would swamp any energy savings in transporting food to the cities.”

Backers say the comparison between conventional and vertical farming isn’t apples to apples, since the government heavily subsidizes expenses including crop insurance for traditional agriculture, greatly reducing the costs involved and the risks that farmers face from unpredictable weather conditions.

But boosters say the equation will very likely change as severe weather makes indoor farming a safer and more reliable alternative to regular growing. Not only will the rising cost of conventional farming make vertical farms look better in comparison, they say, but vertical farms in some places could end up getting subsidies.

“If we imagine that vertical farming is going to become part of a nation’s food-security program, then naturally this part of the industry needs subsidies,” Plantagon’s Mr. Hassle says.

Dr. Despommier, who is also an adviser to Plantagon, acknowledges that energy use, particularly in artificial lighting, remains a challenge for some vertical farms. But he says the lighting industry has made significant progress in recent years on reducing power consumption for specialized lights to grow plants, and researchers continue to work on the problem.

More broadly, he argues that the idea of vertical farming on a large scale will seem increasingly realistic as techniques evolve. He cites cellphones and plasma-screen televisions as examples of innovations that were unimaginable before their time.

“You have to start small and you have to start at the research level before you jump into the commercial aspect of this thing, but that’s the way all these ideas start,” Dr. Despommier says. “Everything we have in this world of ours started out crazy.”

SOURCE